Brand Summary

Identification

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Cure Method

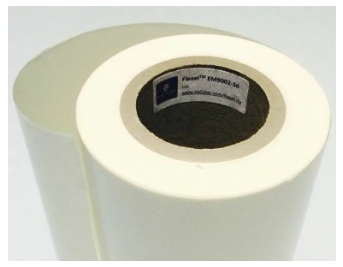

Flexel™ Reactive Film Adhesive Formulations:

These reactive film adhesives come in a variety of formulations. They can be used on many different materials, including aluminum, stainless steel, plastics, textiles, foils, and real and artificial leather. These reactive film adhesives adhere to more materials than heat-activated film without priming.

Flexel™ reactive film adhesives are: