Enhanced TDS

Identification & Functionality

- RTU Product Type

- Technologies

- Product Families

- Product Information

Technology/Base Block Co-Polymer Type of Product Re-sealable Gasket Components One Component Curing Non-Reactive Consistency Hot Melt

Features & Benefits

- Ready-to-Use Product Features

- Key Attributes

- One component requires no mixing

- Thermoplastic nature allows for ease of use

- Re-sealable capabilities improve serviceability of enclosure

- Suitable for easy processing with proper hot melt dispense systems

- End of life recyclability

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Adhesive & Sealant End Applications

- Application Method

- Coating surface area should be clean and free of any oils, residues, dust, or any other contaminants

- Apply to primary substrate. Primary substrate is the preferred substrate in which the material will remain permanently adhered. Secondary substrate will be married to the primary and material will release from during servicing.

- Apply using appropriate Hot Melt dispensing equipment. Adjust heating and pressure parameters to achieve appropriate flow rate.

- Allow 5 minutes for material to cool to room temperature prior to assembly of enclosure.

Properties

- Color (Properties)

- Mechanical Properties

Value Units Test Method / Conditions Rebound-Post Force to Compress (24 hr) 99 % - Rebound-Post Force to Compress (5 min) 99 % - Tensile Strength 23.1 psi ASTM D412 “Die C” Compression Set (1 week, at 80°C, 50% compression) 50 % recovery - Elongation 500.0 % - Compression Set (1 week, 50% compression) 90 % recovery - Cone Penentration (150g added wt.) 120 ddm ASTM D217 (150g added wt) Force to Compress (50% compression) 45 lbf ASTM (C972) - Adhesive Properties

Value Units Test Method / Conditions 90° Average Peak Load (24 hr after at 12°/min) 1 pli - Tensile Strength (Cross pluck at 0.2°/min) 16 psi - - Rheological Properties

Value Units Test Method / Conditions Specific Gravity 0.94 Water Displacement Viscosity (200°C, Spindle 29, 20rpm) 32000 cPs Brookfield

Technical Details & Test Data

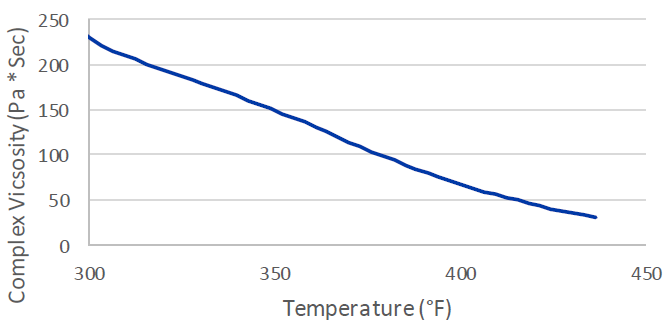

- EV Seal 500 Temperature Visosity Profile

Packaging & Availability

Storage & Handling

- Shelf Life

- 12 Months

- Storage & Handling Information

- Product should be stored at temperature between 8ºC to 28ºC in the unopened container in a dry location.

- Shelf Life: 12 months from date of manufacture.

- Material can typically be peeled or manually removed by hand easily, however, if necessary, mineral spirits can be used to remove excess residue.