Enhanced TDS

Identification & Functionality

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Key Attributes

- Excellent green strength

- Good heat resistance

- Bonds to wide range of substrates

- One component requires no mixing

- Easy processing with proper hot melt dispense systems

- Able to be spray applied

Applications & Uses

- Markets

- Applications

- Application Area

- Application Method

- Application Instructions

- Coating surface area should be clean and free of any oils, residues, dust, or any other contaminants

- Apply to primary substrate. Primary substrate is the preferred substrate in which the material will remain permanently adhered. Secondary substrate will be married to the primary and material will release from during servicing

- Apply using appropriate Hot Melt dispensing equipment. Adjust heating and pressure parameters to achieve appropriate flow rate

- Allow 5 minutes for material to cool to room temperature prior to assembly of enclosure

Properties

- Color (Properties)

- Appearance

- Amber

- Physical Properties

Value Units Test Method / Conditions Thermal Conductivity 0.22 W/m-K - Adhesion Properties

Value Units Test Method / Conditions Static Shear (4 mils; at 23°C) 15 days - Rheological Properties

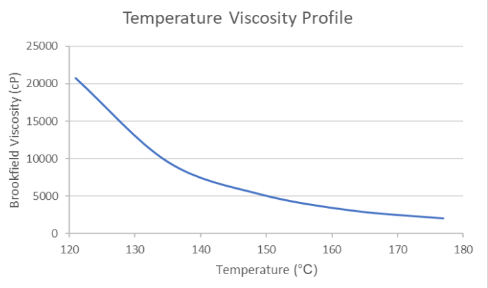

Value Units Test Method / Conditions Viscosity (at 121°C, Brookfield #27, 20 RPM) 20,750 cP Viscosity (at 135°C, Brookfield #27, 20 RPM) 9,575 cP Viscosity (at 149°C, Brookfield #27, 20 RPM) 5,250 cP Viscosity (at 177°C, Brookfield #27, 20 RPM) 2,000 cP Specific Gravity 0.96 Water Displacement

Technical Details & Test Data

- Temperature Viscosity Profile

* Recommend operation dispense temperature of 300° - 345°F

Packaging & Availability

- Packaging Type

- Regional Availability

- Packaging Informations

Drums: 55 gallons

Storage & Handling

- Shelf Life

- 24 months

- Storage Conditions

- Product should be stored at temperature between 8°C to 28°C in the unopened container in a dry location.

- Material can typically be peeled or manually removed by hand easily, however, if necessary, mineral spirits can be used to remove excess residue.