Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

- Base Compound (Liquid State)

Methyl methacrylate

Features & Benefits

- Ready-to-Use Product Features

- General Information about MMA adhesives

2-component methacrylate adhesives belong to the group of reactive adhesives. The reaction starts by mixing hardener and resin. Cyberbond offers these adhesives in double cartridges in 1:1 or 10:1 ratio with static mixing tubes. This allows an easy and quick application. Methacrylate adhesives are available in different viscosities from liquid to paste-like and with different curing times. They are characterized by excellent adhesion to metals, many plastics and composite materials. The mechanical properties range from flexible to rigid.

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Clean Surface

Surfaces should be clean, dry and free of grease before bonding.

Properties

- Physical Properties

Value Units Test Method / Conditions Cure Time (Full, Polymer) 24 h - Mix Ratio (Liquid state) 1:1 - - Density (A/B, Liquid state) 1.07 g/cm³ - Open Time (Liquid State) 15 - 20 minutes - Fixture Time (Liquid State) 20 - 40 minutes - Flashpoint (Liquid State) 10.0 °C - Viscosity (Cone/plate, at 20°C at 160 s⁻¹) 10.000 - 25.000 mPa.s - Viscosity (Cone/plate, at 20°C at 0.5 s⁻¹) 80.000 - 140.000 mPa.s - Temperature Range (Polymer) -50 - 120 °C - Elongation at Break (Polymer) 150 - 200 % - E-Modulus (Polymer) 400 - 600 MPa - Tensile Strength (Polymer) 12 - 16 MPa - - Typical Properties

Value Units Test Method / Conditions Set Time 20 - 40 min - Storage Temperature 10 - 20 °C -

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Property Details & Graph

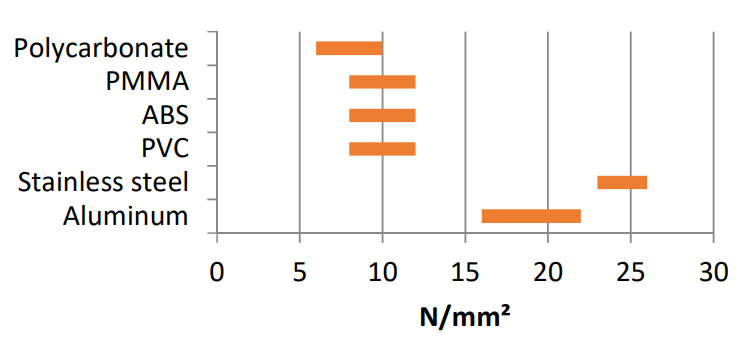

Adhesive performance Tensile shear strength

Substrate, Result N/mm² Tensile shear strength (Polycarbonate,Fail) 6 - 10 Tensile shear strength (PMMA, Fail) 8 - 12 Tensile shear strength (ABS, Fail) 8 - 12 Tensile shear strength (PVC, Fail) 8 - 12 Tensile shear strength (Stainless steel) 23 - 26 Tensile shear strength (Aluminum) 16 - 22 Tensile shear strength

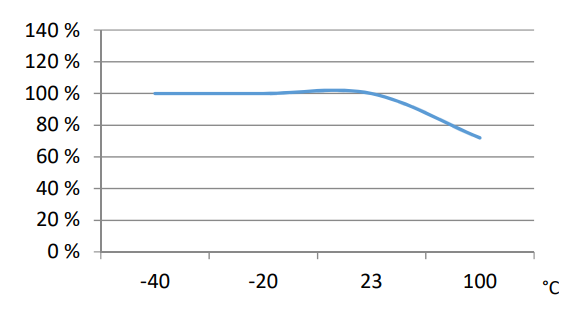

Hot strength tested at temperature

Resistance against solvents

Solvent Resistance Weak acids very good Weak bases very good Polar solvents limited Strong acids and bases limited Measurement of Viscosity

Viscosity describes the flow-ability of a liquid. Cyberbond measures the viscosity of the products by means of the cone/plate method: the liquid is applied on a panel and a defined cone presses the liquid together and rotates. Newtonian fluids are measured at shear rate 160 s-1, thixotropic products are measured at shear rate 0,5 s-1 and 160 s-1. The viscosity is measured in mPa*s at 20 °C.

Packaging & Availability

- Packaging Type

- Regional Availability

Storage & Handling

- Shelf Life

- 12 Months

- Storage Conditions

Store products in a cold and dark place at temperatures between 10°C to 20°C.