Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

- Base Compound (Liquid State)

Methyl methacrylate

Features & Benefits

- Ready-to-Use Product Features

- Product Highlights

Cyanoacrylates are fast setting, one component and solvent free adhesives. They are based on esters of cyanoacetic acid. To get to a finished product, mainly thickeners, respectively film forming agents (polymer methacrylics and acrylics) and stabilizers are added. The polymerization is initiated by present humidity. Best results are given between 40 to 70 % relative humidity.

Cyberbond standard grades are as follows:

- Powerdrop series (stabilized ethyl ester)

- Elastomer and plastic series (ethyl ester)

- Neomer Series (surface insensitive ethyl ester)

- xtraflex series (rubber toughened ethyl ester)

- metal series (ethyl ester)

- low odor series (alkoxy ester)

- medical series (butyl- and octyl ester)

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Resistance Against Solvents

Solvent Resistance Weak acids Very Good Weak bases Very Good Polar solvents Limited Strong acids and bases Limited - Clean Surface

Surfaces should be clean, dry and free of grease before bonding.

Properties

- Physical Properties

Value Units Test Method / Conditions Cure Time (Full, Polymer) 24 h - Mix Ratio (Liquid state) 1:1 - - Density (Liquid state) A/B : 1.07 g/cm³ - Open Time (Liquid state) 40 - 60 sec - Fixture Time (Liquid state) 4 - 7 minutes - Flash Point (Liquid state) 10.0 °C - Viscosity (at 20°C, 0.5 s⁻¹) 10 - 20 mPa.s Cone-plate Temperature Range (Polymer) 50 - 120 °C - Elongation (at Break, Polymer) 180 - 220 % - Young's Modulus (Polymer) 150 - 300 MPa - Tensile Strength (Polymer) 9 - 12 MPa - - Typical Properties

Value Units Test Method / Conditions Storage Temperature 10 - 20 °C -

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Technical Details

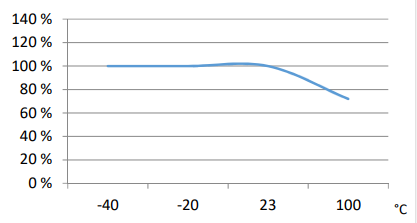

Hot Strength

Tested at temperature.

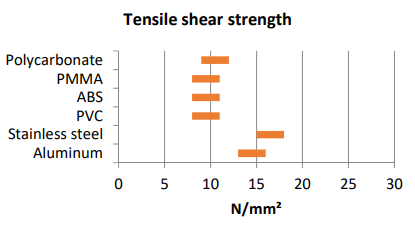

Adhesive performance

Tensile shear strength

Substrate N/mm² Polycarbonate ▲ 9 - 12 PMMA ▲ 8 - 11 ABS ▲ 8 - 11 PVC ▲ 8 - 11 Stainless steel 15 - 18 Aluminum 13 - 16 ▲ Substrate failure

- Measurement of Viscosities

Viscosity describes the flow-ability of a liquid. Cyberbond measures the viscosity of the products by means of the cone/plate method: the liquid is applied on a panel and a defined cone presses the liquid together and rotates. You differentiate between a Newtonian and a thixotropic liquid. In terms of a Newtonian liquid you will get a relative constant viscosity graph in dependence of the rotary speed of the cone. In terms of thixotropic liquids the product becomes more liquid (down to its base viscosity) the faster the cone rotates. The viscosity is measured in mPa*s (milli Pascal x second) [SI system] or in cP (centipoise) [CGS- system]; 1 mPa*s = 1 cP. In order to allow products comparison all adhesives are measured at the same rotation speeds.

- Newtonian liquids at 160 upm

- Thixotropic liquids at 0,5 upm and at 160 upm

Temperature always is at 20 °C / 68 °F, if not mentioned to be different.

Safety & Health

- Safety Information for MMA adhesives

Keep the workplace clean and use in well ventilated areas only. Installll suitable exhaust system at the workplace. Wear suitable safety glasses and gloves. Keep away from heat, hot surfaces, sparks, open flames and other ignition sources.

Packaging & Availability

- Packaging Type

- Regional Availability

Storage & Handling

- Shelf Life

- 12 Months

- Storage Conditions

Store products in a cold and dark place at temperatures between 10°C to 20°C.