Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Benefits

- Bedding compound for teak decks

- Overpaintable after curing

- Good resistance to humidity and weathering

- Extensive bonding of teak decking

- Resistant to temperature from -40°C to +90°C (for short intervals up to +120°C)

- Meets the requirements of the International Maritime Organization

Applications & Uses

- Markets

- Applications

- Application Area

- Application Method

- Cure Method

- Processing

Processing temperature: +5°C to +35°C

Preparation:

- The surfaces to be bonded must be clean, dry and free from dust and grease. For cleaning we recommend Körasolv PU. In the case of powder coated substrates, Körasolv WL should be used.

- To increase bond strength of non-porous substrates such as glass, glass-fiber reinforced plastics, gel coat, aluminum, stainless steel, etc. we recommend the use of Körabond HG 81. For porous substrates such as wood, Körabond HG 74 E is recommended. For certain plastics such as ABS or PVC we suggest the use of Körabond HG 77.

- Due to the diversity of substrates, preliminary tests are necessary.

Bonding:

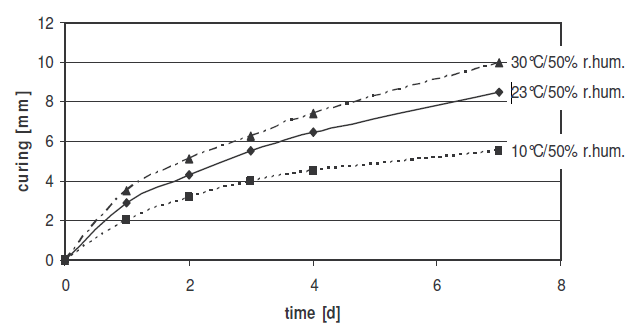

The thickness of the layer depends on the expected mechanical movement. Join the materials to be bonded within the skin formation time. We recommend mechanical fixing until a complete cure is obtained. The curing time depends on temperature, humidity and the dimensions of the joint. When necessary, the curing can be improved by water spraying. This may be required in winter.

Cleaning:

To remove uncured adhesive, use Körasolv PU. Cured adhesive can only be removed mechanically.

Properties

- Technical Data

Value Units Test Method / Conditions Density 1.3 g/cm³ - Processing Temperature 5 - 35 °C - Skin Formation Time 75.0 min DIN 50 014, NC 23/50-2 Curing Time (on the first day) 3.0 mm DIN 50 014, NC 23/50-2 Change in Volume 5.5 % DIN 52 451 Hardness 45.0 - DIN 53 505, Shore A Elongation at Tear 800.0 % DIN 53 504 Tensile Strength 3.0 N/mm² DIN 53 504 Tear Propagation Strength 8.0 N/mm DIN 53 515

Regulatory & Compliance

- Certifications & Compliance

Safety & Health

- Precautions

- When using Körapur 928 Marine, avoid direct skin contact of the uncured material.

- Wear suitable personal protective equipment (chemical resistant gloves/clothing).

- Users should always refer to the Central Association of the Mutual Industrial Accident Insurance Funds, Central Office for Accident Prevention, when processing PUR-coating materials.

Packaging & Availability

- Packaging Type

- Regional Availability

- Packaging Information

- 600 ml sausage (carton a 12 pcs.)

- 12 kg tin

Storage & Handling

- Shelf Life

- 12 months (sausages), 9 months (tins)

- Storage Condition

Do not store at temperatures above 25°C.