Enhanced TDS

Identification & Functionality

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features & Benefits

- Good flame resistance

- High compressive strength and compressive modulus of elasticity

- Low absorption of water and oil

Applications & Uses

- Markets

- Applications

- Application Area

- Cure Method

- Application Instructions

- Materials required: foam damming materials, metal dams, sealing adhesive, release agent, washing agent or acetone, heavy duty hand electric drill with an operating speed of 200 rpm, jiffy mixer, knife, infrared thermometer, heater (used when the temperature is below 13℃), protective gloves and goggles.

- TS365 marine chocking compound: try to store the adhesive at (23±2)℃ for at least the last 12 hours before use.

- Clean: clean all surfaces that the adhesive will contact, they should be free from grease, oil, water, rust or paint.

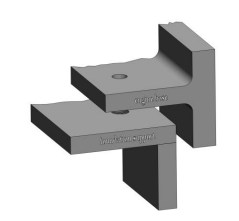

- Adjustment: the machine’s alignment and the casting cavities should be adjusted to the required size through the adjustable bolts, wedge blocks and so on.

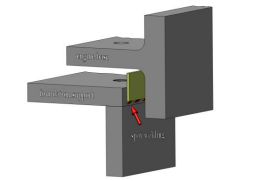

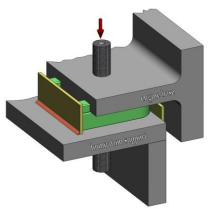

- Damming: Attach the iron behind between the body base and engine base to support the follow-up of foam sealing material.

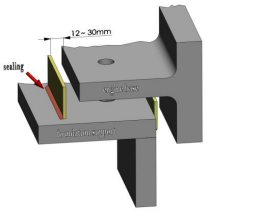

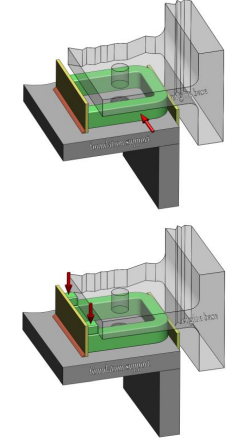

Attach the iron front between the body base and engine base to form the pouring area, the height and distance from the base should be accorded with limits shown. And leak the attachment with the sealant adhesive.

Insert foam damming materials per chocking area

Insert foam damming materials in bolt hole.

The general rule: form a blocking cavity with no leaks, the foam damming materials and sealant adhesive can be used.

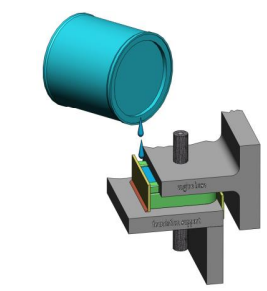

- Mixing: according to the list instructions of “mixing ratio-temperature-thickness”, add appropriate hardener to the resin, and mixing with heavy duty hand electric drill, usually less than 3 minutes.

Thickness 30 mm 50 mm 70 mm Temperature <15C° No reduction 2/4 reduction 3/4 reduction 15°C-19°C No reduction 2/4 reduction 3/4 reduction 20°C-23°C No reduction 3/4 reduction or full reduction 3/4 reduction or full reduction

24°C-25°C 1/4 reduction or no reduction full reduction full reduction 25°C-30°C 1/4 reduction or no reduction full reduction Layered pours - Pouring: pour the mixture as soon as possible after mixing from the over pour area. Make sure the adhesive surface higher than the bottom of engine base at least 12 mm.

- Samples: pour the mixture about 300 g to the appropriate small box, after curing test Barcol hardness.

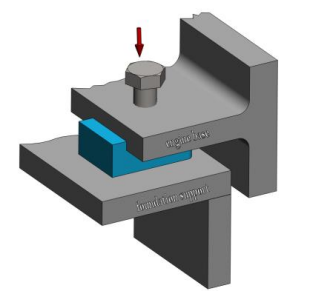

- Curing: It is appropriate when Barcol hardness of samples and chocks is higher than 35. Make sure the temperature is at least 13 ℃ , use heater if necessary.

- After curing: remove the iron dams, take the sharp edge off the over pour; adjust the adjustment bolts and wedge blocks; tighten the hold down bolts to the desired tension or torque.

Properties

- Component A

Value Units Test Method / Conditions Viscosity (Resin, at 23°C, 3 rpm) 50,000 - 100,000 mPa·s Brookfield DV2T Viscometer Density (Resin) 1.86 g/cm³ ISO 1675 - Component B

Value Units Test Method / Conditions Viscosity (Hardener, at 23°C) 26.0 mPa.s Brookfield DV-Ⅱ+ Pro Viscometer Density (Hardener) 0.97 g/cm³ ISO 1675 - Typical Properties

Value Units Test Method / Conditions Density (Mixed) 1.78 g/cm³ ISO 1675 - Thermal Properties

Value Units Test Method / Conditions Glass Transition Temperature 121.3 °C ISO 11357-2 Burning Rate 0.0 mm/min ASTM D635 - Cured Properties

Value Units Test Method / Conditions Recommended Cure (at 60°C) 8.0 h - Recommended Cure (at 23°C) 24.0 h - Fixture Time 50 - 70 min - Cure Temperature (at 23°C) 24.0 h - Barcol Hardness Curing (at 60°C, 8h) 45 - 55 - EN 59 (re. ASTM D2583) Compressive Strength Curing (at 60°C, 8h) 138.3 MPa ISO 604 Compressive Modulus of Elasticity Curing (at 60°C, 8h) 6756.3 MPa ISO 604 Tensile Strength (at 60°C, 8h) 47.4 MPa ISO 527-2 Tensile Modulus of Elasticity Curing (at 60°C, 8h) 8784.2 MPa ISO 527-2 Notch Impact Strength Curing (at 60°C, 8h) 2.5 kJ/m² ISO 180 Water Absorption Curing (at 60°C, 8h) 0.267 % ISO 175 Oil Absorption Curing (at 23°C, 8h, CD40) 0.039 % ISO175 Oil Absorption Curing (at 23°C, 8h, CH40) 0.033 % ISO175 Bending Strength Curing (at 60°C, 8h) 75.2 MPa ISO 178 Bending Modulus Curing (at 60°C, 8h) 8054.0 MPa ISO 178 Coefficient Curing (at 60°C, 8h) 37.1 ppm/°C ASTM E228 Voluminal Shrinkage Curing (at 60°C, 8h) 0.0058 % ISO 3521 Cure Temperature (at 60°C) 8.0 h -

Packaging & Availability

- Regional Availability

- Typical Packaging

Unit Size - 8 kg/set

Storage & Handling

- Shelf Life

- 12 Months

- Storage

Store in a cool, dry area at a room temperature.