Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- General Instructions

Surfaces to be bonded should be clean and dry and free of grease. Product should be applied in enough quantity to fill all engaged threads. The product performs best in thin bond gaps. Very large gaps may create gaps that will affect the cure speed and overall strength. Good contact is essential. An adequate bond develops in 15 to 45 minutes and maximum strength is attained in 24 hours. This product is not recommended for use in pure oxygen environments and/or oxygen-rich systems and should not be slected as a sealant for chlorine or other strong oxidizing materials. This product is not designed for plastics, particularly thermoplastics where stress cracking of the plastic could result. It is recommended to confirm compatibility of the product with all substrates prior to use.

Properties

- Color

- Physical Form

- Cured Mechanical Properties

Value Units Test Method / Conditions Locking Strength high - - Service Temperature - 55 - 205 °C - Breakaway Torque 50 - 150 in-lb - Prevailing Torque min. 200 - - Pin/Collar Shear Strength 2000.0 psi - - Technical Data

Value Units Test Method / Conditions Specific Gravity 1.1 - - - Cured Properties

Value Units Test Method / Conditions Full Cure Conditions 24.0 h - Cure Appearance Green solid - - - Uncured Properties

Value Units Test Method / Conditions Flash Point min. 93 °C - Gap Fill 0.01 inch - - Rheological Properties

Value Units Test Method / Conditions Viscosity (at 0.50 rpm) 400 - 800 cP Brookfield - Specifications

Mil-R-46082B, Type II; ASTM-D5363 AN 0412

Technical Details & Test Data

- Curing Performance

The rate of cure will depend on environmental conditions and the substrates used. The gap of the bond line will affect set speed. Smaller gaps tend to increase set speed. Activators may be applied to further improve set speed, but may also impair overall adhesive performance.

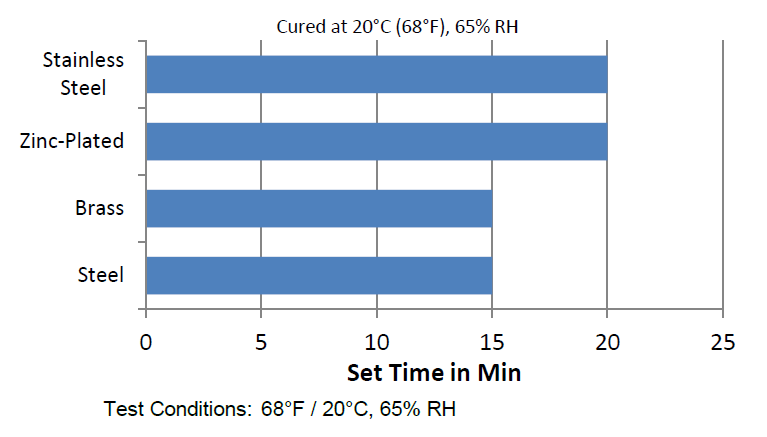

- Set Time on Various Substrates

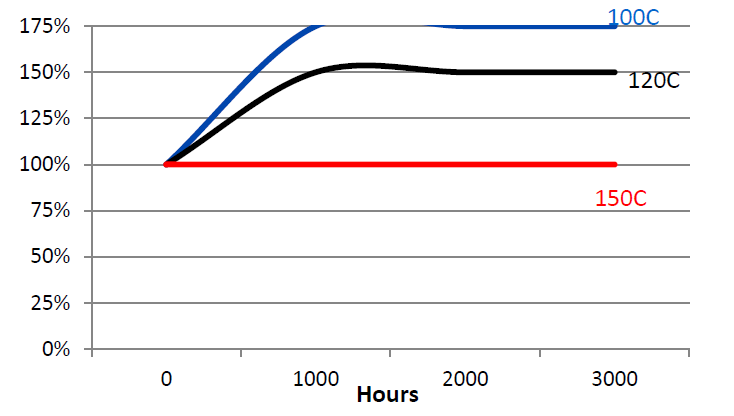

- Heat Aging (aged at temperature indicated and tested at 22°C)

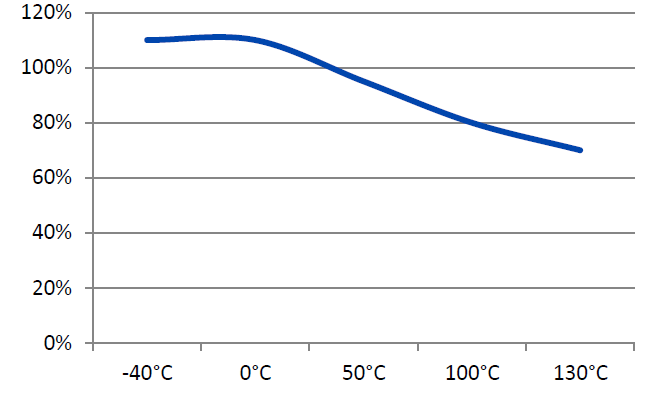

- Hot Strength (%RT strength, tested at temperature)

- Solvent Resistance

Solvent Example Resistance Alcohol Ethanol, Methanol

+ + + Ester (aromatic) Ethylacetate – – – Ketone (aromatic) Acetone, Benzophenone

– – – Aliphatic hydrocarbon (alkanes) Petrol, Heptanes, Hexane

+ + – Aromatic hydrocarbons Benzyl, Toluol, Xylol

+ + – Halogenated hydrocarbons Methylenchloride, Chloroform, Chlorobenzol

– – – Weak aqueous Nitrite, muriatic acid, sulphuric acid, phosphoric acid

+ + + (– – – if concentrated) Weak aqueous base sodium hydroxide solution, caustic potash

+ + + (– – – if concentrated)

Packaging & Availability

- Regional Availability

Storage & Handling

- Shelf Life

- 12 Months

- Storage Conditions

- Storage Temperature: 20°C.

- Products should be stored unopened in a cool, dry place out of direct sunlight. Products may be refrigerated for improved shelf life, but should be brought back to room temperature before use.