Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

Applications & Uses

- Markets

- Applications

- Application Area

- Application Method

- Compatible Substrates & Surfaces

- Cure Method

- Use Precautions

Product is ready-to-use as received; do not dilute hot melt adhesive. Confirm compatibility before making hot melt adhesive changes.

- Suggested Application

- 2U210 is specifically formulated for technical laminating applications where resistance to highly humid environments and flame resistance are needed.

- 2U210 exhibits high tack, long open time, excellent specific adhesion and is recommended for simultaneous back coating and foam laminations.

- It is also recommended for fabric to fabric laminations where 2U210’s medium viscosity and high tack allow for very low coating weights to achieve destructive bonds.

Application Temperature 230 - 250ºF Equipment Types / Method Rotogravure & Screen Print, Slot Die Extrusion, Fiberized Spray and Roll Coat

Recommended Coating Weights

Apparel: 8-12 GSM

Technical: 14-20 GSM

Properties

- Typical Properties

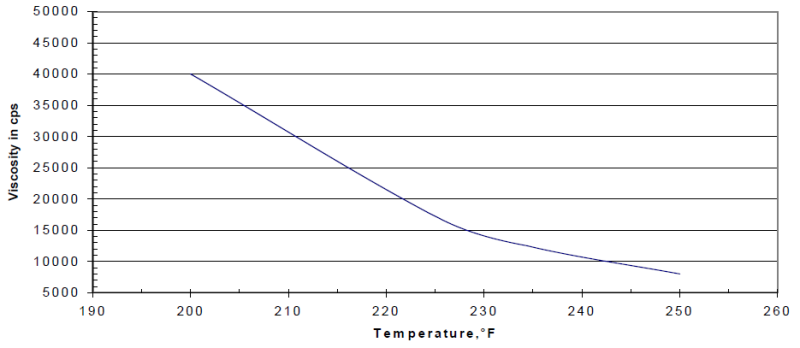

Value Units Test Method / Conditions Viscosity (at 250°F) 8000.0 cP - Open Time 1.0 min - Green Strength Build (at 30s) min. 50 psi - Tensile Strength 3500.0 psi - Elongation 500.0 % - Cure Rate (at 21 - 25°C, 45 - 55% relative humidity, in 24h)* 75.0 % -

Technical Details & Test Data

- Viscosity Curve

2U210 viscosity versus temperature

Packaging & Availability

Storage & Handling

- Storage Condition

To ensure maximum stability, product should be stored in the original closed container in an interior location capable of maintaining a constant temperature.