Enhanced TDS

Identification & Functionality

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Cure Method

- General Instructions

- Surfaces to be bonded should be clean and dry. Dispense a drop or drops to one surface only. Apply only enough to leave a thin film layer after compression. Press parts together and expose to UV dose when ready.

- An adequate bond should develop rapidly, depending on UV dose efficacy, and maximum strength is attained in 24 hours.

- Wipe off excess adhesive from the top of the container and recap. products, if left uncapped or exposed to sunlight, may deteriorate or cure prematurely.

Properties

- Appearance

- light straw liquid

- Cured Mechanical Properties

Value Units Test Method / Conditions Hardness 70 Shore D ASTM D2240 Elongation to Break 175 % ASTM D638 - Technical Data

Value Units Test Method / Conditions Viscosity (20°C to 25°C) 850 - 1150 cPs Specific Gravity 1.06 - Cured Properties

Value Units Test Method / Conditions Flash Point min. 95 °C Set Time and Wavelength (at 395nm, 50mW/cm²) max. 6 sec Full Cure Time 24 hours Optimum Wavelength 300 - 420 nm Cured Appearance Colorless solid - Curing Performance

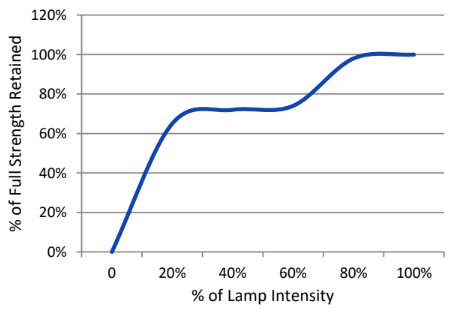

- Photoinitiation initiates the curing process. Handling strength is reached in a short time, and will vary based on UV dose efficacy, environmental conditions, bond line gap, and other factors.

- Product will continue to cure for at least 24 hours before full strength and solvent resistance is developed.

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Percent Strength Retained at Given Dosage

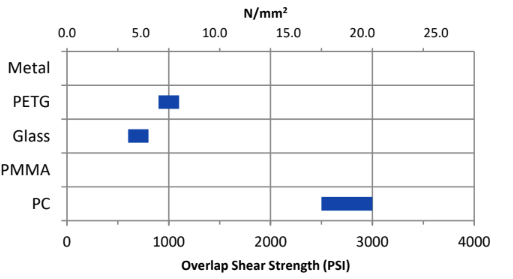

- Performance of Cured Adhesive

Substrate N/mm² PSI Metal n/r to n/r n/r to n/r PETG 4.1 to 5.5 600 to 800 Glass 6.2 to 20.7 2500 to 3000 PMMA 17.2 to 7.6 900 to 1100 PC n/r to n/r n/r to n/r * n/r = not recorded on this substrate

- Performance Range by Substrate

Packaging & Availability

- Country Availability

- Regional Availability

Storage & Handling

- Shelf Life

- 9 months

- Storage Conditions

- U304 should be stored unopened in a cool, dry place out of direct sunlight. U304 should be kept at room temperature away from direct light.

- Protect from extreme heat or cold, do not refrigerate.

- Storage Condition : 8°C to 21°C in darkness