Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features & Benefits

- Low surface energy substrate bonding modified acrylate adhesive

- Room temperature cure

- Ability to bond PE/PP/LDPE/HDPE/TPO

- No pre-treatment of the substrates needed

- Excellent water and humidity resistance

- Solvent-free of adhesive system

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Cure Method

- General Instructions

- For best performance bond surfaces should be clean, free of grease and all other surface contaminants.

- It is recommended that either meter mix equipment or cartridges with static mix nozzles be used to ensure the proper 10:1 mix ratio and dispense the adhesive. Hand mixing is not recommended and may result in unpredictable results.

- Lower temperature will diminish the reactivity of the product, and higher temperature will speed up curing process. The recommended temperature of the working circumstance is 15~30°C.

- To assure maximum bond strength, surfaces must be mated within the adhesive’s open time. Use enough material to completely fill the joint when parts are clamped.

- Do not return unused material to container as it would result in contamination and/or premature hardening of contents

Properties

- Color (Properties)

- Typical Properties

Value Units Test Method / Conditions Mixed Density 1.0 g/cc GB/T 13477.2 Volume Mix Ratio 10:1 - - - Uncured Properties

Value Units Test Method / Conditions Open Time 2 - 3 min - Cure Temperature Room temperature - - Cure Time 24.0 h - Over Lap Shear Strength (Carbon steel, adhesive failure) 7.2 MPa GB/T 7124 Over Lap Shear Strength (Aluminum, adhesive failure) 7.3 MPa GB/T 7124 Over Lap Shear Strength (Acrylonitrile Butadiene Styrene) 4.9 MPa GB/T 7124 Over Lap Shear Strength (FRP, Cohesive failure) 5.2 MPa GB/T 7124 Over Lap Shear Strength (Polycarbonate, cohesive failure) 3.2 MPa GB/T 7124 Over Lap Shear Strength (High Density Polyethylene) 5.7 MPa GB/T 7124 Over Lap Shear Strength (Polypropylene) 6.0 MPa GB/T 7124 - Rheological Properties

Value Units Test Method / Conditions Viscosity (Resin, spindle 7, 2 rpm, at 25°C) 250,000 - 500,000 cP Brookfield Dv-II Viscosity (at 25°C, 2 rpm) 40,000 - 60,000 cP Activator Brookfield Dv-II #7 - Note

- CF = Cohesive Failure

- AF = Adhesive Failure

- MM = Mixed (Mode of AF and CF)

- SF = Substrate Failure/Break/Yield

Technical Details & Test Data

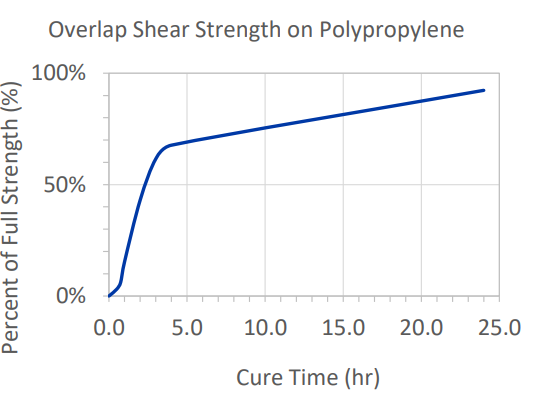

- Time Until Full Cure (% of RT strength) Image

Packaging & Availability

- Regional Availability

Storage & Handling

- Handling and Clean-Up

Clean up is best before the adhesive has cured. Cleaners containing NMP (N-methyl pyrolidone) or Citrus terpene provide the best results. On cured adhesive repeat use may be required.

- Storage

For maximum shelf life, TS880 Acrylic-based Structural Adhesive should be stored in a cool, dry area at below 4°C. When stored at the recommended temperatures in the original unopened containers, this product has a shelf life of six months from date of shipment.