Enhanced TDS

Features & Benefits

- Ready-to-Use Product Features

- Product Attributes

Features Benefits VOC <250 g/l Approved for use in all regulated areas

Quick and easy application Reduce labor cost, and minimal clean up

Good adhesion to EPDM, TPO & Fleeceback membrane Tenacious bonding performance

Fast drying, <7 minutes in most minutes in most conditions Allows for faster membrane lay-in

Can be applied at low temperature (25°F) Extended roofing season time

Extended open time, up to 30 min at 160°F Provides flexibility to installation time

Applications & Uses

- Markets

- Applications

- Application Area

- Application Method

- Compatible Substrates & Surfaces

- Basic Use

The adhesive is applied in a variable web spray pattern via a self-contained spray system. Product is applied full coverage to adhere Fleeceback and standard EPDM and TPO membranes to approved insulation, cover board, OSB etc. The adhesive must be applied to both the membrane and substrate to which it will be mated. Once dry the membrane can be mated to the substrate and brushed in.

- Approved Substrates

Acceptable substrates include: Polyiso, Polyiso HD, DensDeck® Prime, SECUROCK®, OSB, plywood, metal, residual asphalt, and clean concrete block.

Applying an initial coat of adhesive reduces the potential for asphalt bleed- through on vertical surfaces. The initial coat serves to seal the surface of residual asphalt and improves adhesion. Once the initial coat has flashed off properly, apply a second coating of Millennium Sprayable Single-Ply Bonding Adhesive to the vertical surface.

- Approved Membranes

Fleeceback and standard EPDM and TPO membranes.

- Surface Preparation

All work surfaces should be clean, dry, and free of dirt, dust, debris, oils, unadhered coatings, deteriorated membrane or other contaminants that may result in a surface that is not sound or is uneven.

- Limitations

Not for use on PVC or KEE membranes.

- Equipment

Hose and spray gun must be purchased separately.

- Clean-Up

Solvent or mineral spirits can be used to clean tools and surfaces. If the spray gun valve becomes stuck, attach hose and spray gun to container of Citrus Cleaner, MEK, Acetone, Toluene, etc and trigger spray gun repeatedly until operation is smooth. If the spray gun is clogged, soak fittings in MEK, Acetone, Toluene, etc to loosen adhesive. Observe all manufacturer’s safety precautions and use recommendations when using solvents.

To prevent material from hardening in spray gun and hose, do not evacuate hose and spray gun unless connecting to a new canister. Use mineral spirits to clean adhesive residue from spray gun and spray tips.

Dispose canister when all adhesive in the canister has been used, close canister valve and evacuate hose and spray gun before disconnecting hose from canister. Dispose of contents/ adhesive canister in accordance with local/regional/ national/international regulations.

- Application Instructions

- Shake adhesive canister for 30 seconds prior to use.

- Attach spray gun to hose and then attach hose to adhesive canister. Open valve on canister and check connecting fittings for leaks. Once valve has been turned on, do not turn the valve off until the adhesive canister is completely empty or proper cleaning (see instructions below) is performed.

- Millennium Sprayable Single-Ply Bonding Adhesive can be applied at ambient temperature of 25°F and above. Adhesive canister temperature must be at least 70°F prior to use for the product to spray properly. Utilize an H.B. Fuller warming blanket or hot box when necessary. Substrate must be clean, dry, and free of debris and contaminants.

- Adjust the spray pattern/fan by slowly adjusting trigger lock to the desired pattern and locking when not in use.

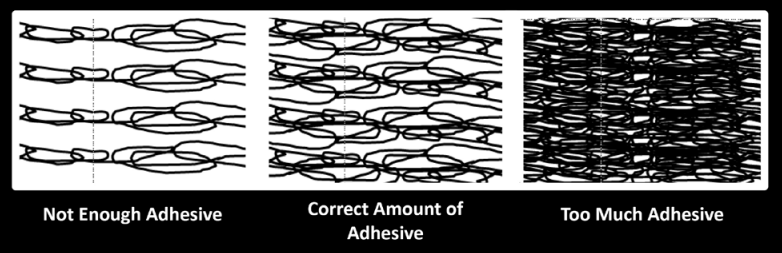

- Visually target the “Correct Amount of Adhesive” coverage pattern detailed in the image below. Typically spray with the trigger fully open, at a height of ~12 inches, and a rate ~1ft/sec to obtain “Correct Amount of Adhesive” spray pattern. Apply adhesive with proper overlap to ensure adequate adhesive coverage.

Figure: Adhesive Spray Patterns

- Apply Millennium Sprayable Single-Ply Bonding Adhesive in an even coat to deck substrate and membrane, keeping the spray tip approximately 12” (30.5 cm) away and perpendicular to the surface during spray. Avoid high thickness buildup.

- For applications taking place in ambient temperature below 70°F, store adhesive canister in heated space and move to project area during application. Adhesive canisters must be kept warm on the jobsite. Dispense product from canister while it is still warm. Adhesive will begin to spit rather than spray when the adhesive in the canister is too cold. If this occurs, swap cold canister for warmer one and return cold canister to heated area. Before changing canister, close the valve on the canister and depressurize the hose. Remove the hose and attach to the new canister. Open valve and do a test spray.

- Allow Millennium Sprayable Single-Ply Bonding Adhesive to flash-off until it does not transfer to finger when touched. Limit application to surfaces that will be covered with membrane the same day.

- Follow OEM membrane manufacturer’s guidelines when laying membrane into adhesive.

Safety & Health

- Safety Information

- Millennium Sprayable Single-Ply Bonding Adhesive contains a flammable liquid propellant and vapor.

- Vapors from applied adhesive are heavier than air and may travel along the ground or through ventilation and ignited by pilot lights, other flames, sparks, heaters, smoking, electrical motors, static discharge, or other ignition sources.

- Residual vapors may ignite even though adhesive is not being applied.

- Keep away from open flame.

- Use in well ventilated areas. Avoid inhalation of spray mist or vapors.

- Appropriate PPE, gloves and goggles must be worn when using this product.

- Never aim spray gun at people.

- Read label and safety data sheet prior to use for complete safety, precaution and warning information.

Packaging & Availability

- Regional Availability

- Packaging and Coverage

Item Part # #38 canister 15268-CST31A Spray Gun 30004-004 6’ Hose 30001-004 12’ Hose 30002-004 18’ Hose 30003-004 Extended Applicator 30005-004 Canister Flush 15413-CST8 LVOC Canister Flush 15414-CST8 Applicator Tips 30006-004 Coverage rate is 1000 ft² /canister for finished two sided application when laminating smooth field membrane to board stock/substrate. Coverage rates may vary with fleece membrane

Coverage rate is 750 ft² /canister for two sided vertical wall application when laminating smooth field membrane to wall substrate. Coverage rate for this application is decreased due to increased overlap of spray pattern for the vertical application.

Coverage rates may be lower when used over irregular surfaces and will vary depending on roughness of membrane/substrate surfaces.

Storage & Handling

- Shelf Life

- 12 months

- Storage Conditions

Store canister in a safe, conditioned space with temperature maintained above 70°F. Do not store canister in areas where temperatures reach 110°F or higher. Contents are flammable. Store in accordance with local, state, and federal regulations.

With the hose and applicator attached, keep canister valve open to maintain pressure in the hose and spray gun. Periodically spray in a safe manner to help prevent possible clogging. Keep spray applicator trigger locked when not in use. Shelf life is 12 months in unopened packaging and stored at temperatures of 40°F to 100°F.