Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Convenient Drying: Premier® Plus achieves 30% strength in 24 hours, full cure in 7 days. Curing time depends on temperature, amount of product used, porosity of substrate, and amount of air reaching product.

- Easy Working Consistency Year-round: Premier® Plus is gunnable from 40°F to 100°F (for best adhesion, the two surfaces must be dry, clean and above 60°F).

- Durable: Premier® Plus remains very flexible enabling it to absorb movement due to expansion and contraction. It will not shrink or become brittle with age.

- Versatile: Gunther Mirror Mastics will adhere to a wide variety of substrates including drywall, wood, metals, glass, marble and tile (note installation section).

Applications & Uses

- Markets

- Applications

- Application Method

- Compatible Substrates & Surfaces

- Use Level

- 12:1

- Application

Installation

- Check and prepare substrates, all substrates should be plumb and square.

- Check for dampness or the possibility of dampness occurring after installation.

- Check for unsealed surfaces, loose plaster, dust, or poor quality/loose paint.

- Oil based paints found in older construction can become very brittle in time and cannot be depended upon to support a mirror.

- Also some lower cost primers dry with a powdery surface which makes adhesion impossible.

- Sand through to the base surface where the product will be applied.

- Clean the area and seal with a good quality, environmentally safe, acrylic sealer (Gunther Prime-N-Seal™).

- Most substrates need to be sealed. Lacquer sealers should not be used. Many lacquer sealers are not effective on drywall or wood.

Application

- Premier® Plus should be applied only in vertical beads the length of the mirror, 5 - 6” apart. Allow 3” from the mirror edge to begin or end a bead.

- Do not apply mastics in a circle where an air pocket could collect solvents and possibly extract material that could be damaging to the mirror. The best way to apply Premier® Plus from a cartridge is to start from the center and let the mastic naturally expand out as it is being gunned.

- Mechanical support systems are recommended for all mirror applications. This includes the use of mechanical fasteners at the top and bottom of the mirror.

Substrates

- Concrete, plaster, drywall and sheet rock, hard board, chipboard, green board. All porous substrates such as those listed above should always be sealed. A sealer adds strength to the wall and prevents caustic chemicals from attacking the mirror backing.

- Chipboard, or Particleboard: Is produced with wax in the molding process. Because the was is fused to the wood particles, wax will be present on the board surface. Sealers will not adhere to wax. Sand the chipboard or particleboard before applying sealer; green board also must be sealed because it contains chemicals that cause silver deterioration.

- Acrylic Mirror/Painted Glass: Premier® Plus is recommended for acrylic mirror by the manufacturer. Premier® Plus can also be used on painted glass.

- Do not apply Gunther Mirror Mastics to vinyl backing.

- Wallpaper or Painted Surfaces: Wallpaper does not make a strong substrate for mirror installations. Remove wallpaper and apply mastic directly to the re-sealed wall. Never install mirrors on new plaster or on a painted wall.

- Fire Retardant Plywood and Wolmanized Wood: These are not recommended as substrates when using mirror mastic for mirror installations. Chemicals in the wood will cause loss of adhesion over time.

Coverage

- One 300 ml cartridge with a 3/8” bead coveres 15 lineal feet.

Clean-up

- Remove excess with mineral spirits. On carpet, let product set for 1/2 hour and gently pull from fibers.

Limitations

- Do not use on styrofoam, plastics or acrylic mirror (as noted above Premier® Plus is safe for acrylic mirror meeting federal specs).

- New copper-free, no-lead, low-lead or traditional mirrors that may have changed paint backing need to be tested prior to use of Gunther products.

- Special Applications

- Ceiling Installation: caution should be used in horizontal installations. Glass is a brittle product subject to thermal and seismic shocks, making it difficult to guarantee a permanent ceiling installation. Most organizations responsible for industry installation standards, such as the California Glass Association, do not sanction the practice of mounting mirror on an overhead, horizontal surface.

- Mirror Overlays: Working with mirror strips can be difficult. For overlays, use Premier® Plus to achieve a fast set and strength along with double-faced tape. Premier® Plus has the capability to compress to 1/16”, providing a professional installation. Double-faced tape is used only for initial adhesion to support the mirror. The mastic is for long term adhesion and strength. Mastic beads of 1/4” to 3/8” thick by 6” long, leaving a 3” gap between where the bead starts will improve curing time.

Note: Check with mirror manufacturer on recommended double-faced tape.

- Mirrored Furniture: Close tolerances are very important with mirrored furniture. As previously mentioned, beads should be used to enhance mastic curing and double-faced tape can be used when necessary to support.

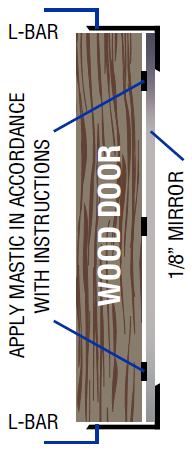

- Mirrored Doors: The diagram (at right) shows a secure method of installing mirror on doors. Make sure the door is not treated with a fire retardant. Also, any varnish or finish on the door should be sanded away where the mastic is to adhere. Allow extra cure time if applying mastic to non-porous substrates.

Properties

- Color (Properties)

- Technical Data

Value Units Test Method / Conditions Viscosity approx. 1,500,000 cP - Mounting Time (Skin) 60.0 min - Mounting Time (Mount) 20.0 min -

Packaging & Availability

- Packaging Type

- Regional Availability

- Packaging

10.3 fl oz cartridge (12/case)

Storage & Handling

- Shelf Life

- 12 Months (Stored at 75°F or lower)

- Storage Conditions

- Store at less than 85°F.

- Freezethaw capability - 7 times.