Enhanced TDS

Identification & Functionality

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Benefits

- Lower application temperature (325ºF - 335ºF) compared to

- polyamide hot melt (375ºF - 425ºF)

- Higher green strength compared to polyolefin hot melts

- Faster set time compared to polyolefin

- Better heat resistance compared to EVA hot melts

- Better low temperature flexibility compared to typical polyamides

- Meets and exceeds Kitchen Cabinet Manufacturers Association (KCMA)

- cabinetry adhesive test standards

- Tougher than typical polyamides

Applications & Uses

- Markets

- Applications

- Application Area

Properties

- Typical Properties

Value Units Test Method / Conditions Bead to Molten 193.0 °F - Transition Temperature 260.0 °F - Open Time 12.0 s - Set Time 15.0 s - Mettler Soft Point 302.0 °F - Ultimate Stress 429.0 psi - Elongation 703.0 % - Peel Adhesion Failure Temperature 184.0 °F - Shear Adhesion Failure Temperature 255.0 °F -

Technical Details & Test Data

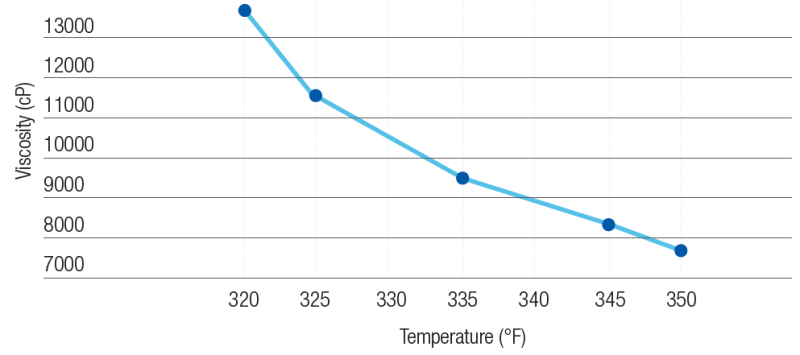

- Viscosity Curve

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Condition

Store material in original unopened packaging at temperatures between 4°C and 32°C. Shelf life is two years minimum when stored as recommended.