Enhanced TDS

Identification & Functionality

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

Applications & Uses

- Markets

- Applications

- Application Area

- Application and Cleaning Instructions

Typical Equipment:

- A hot melt application equipment capable of maintaining the suggested adhesive temperature and appropriate for the application. An inert nitrogen blanket is suggested (not required).

General Application:

- Purge the previous hot melt adhesive from the equipment.

- Set the equipment temperature to the suggested settings.

- Adjust the pump pressure for the desired adhesive amount.

- The open and set time characteristics may be modified with small adjustments to the amount of applied adhesive and equipment temperature settings.

Cleaning:

- Consult the equipment manufacturer for cleanup procedures.

Properties

Technical Details & Test Data

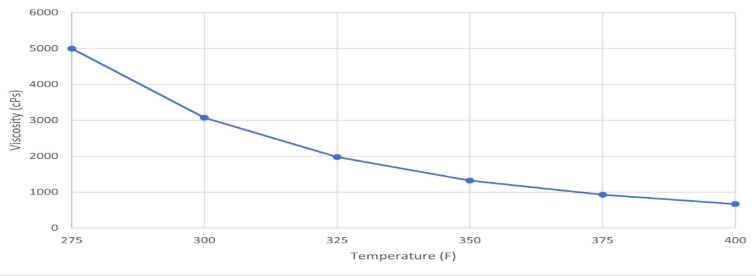

- Viscosity Curve

Packaging & Availability

- Country Availability

- Regional Availability

Storage & Handling

- Shelf Life

- 2 year

- Storage Conditions

Clean and dry conditions above 20 °F and below 120 °F in the original container.

- Safety Information

- To minimize the risk of burns, we recommend the use of eye protection and protective clothing when working near a hot melt applicator. To minimize the risk of flammable vapors, do not exceed a melt temperature above 400 °F.

- Prevent the build-up of vapors. Extinguish all sources of ignition during hot melt use.